sheet metal drawing operation is used to make

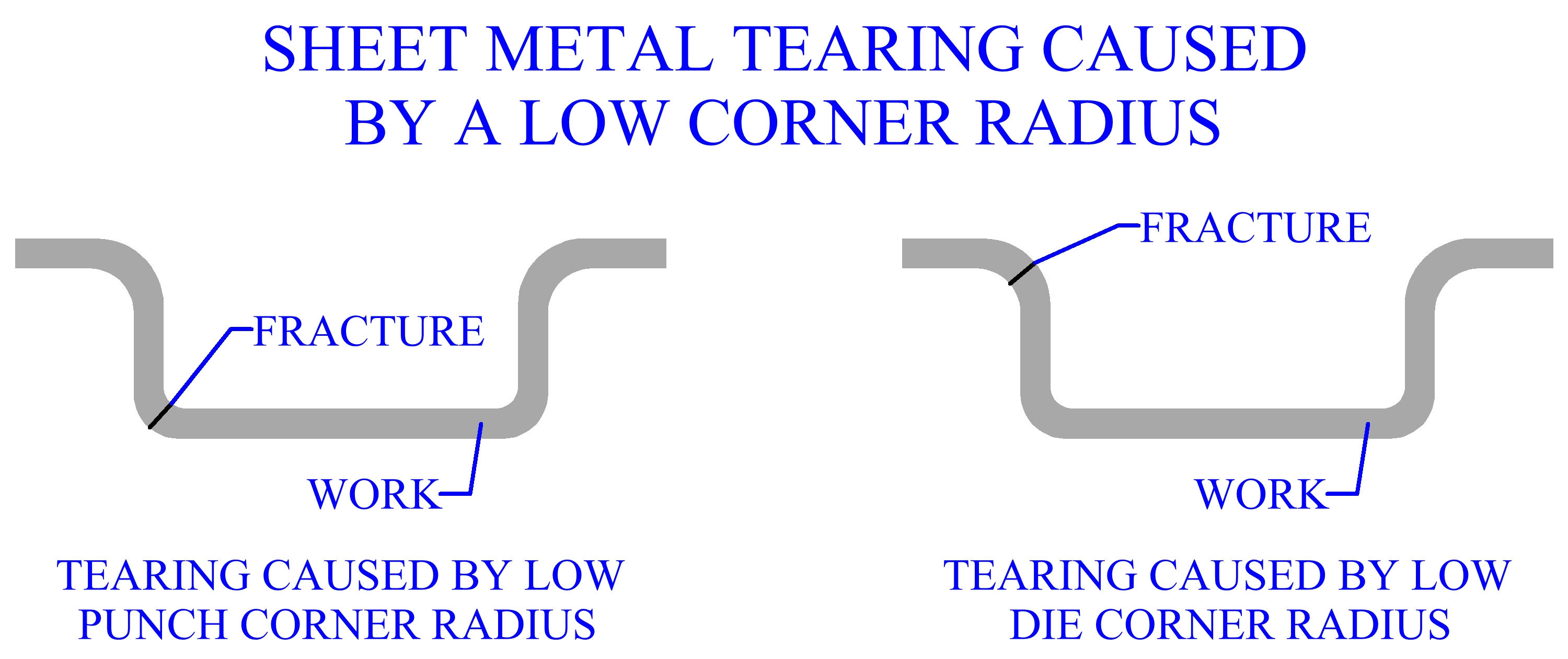

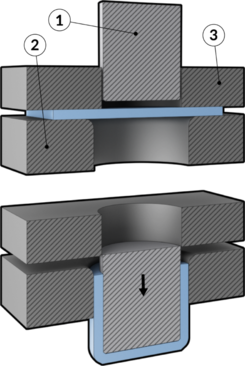

As the metal is drawn it stretches to become thinner to achieve a desired shape and thickness. With the use of the industrial manufacturing process sheet metal is formed by working metal into flat and thin pieces.

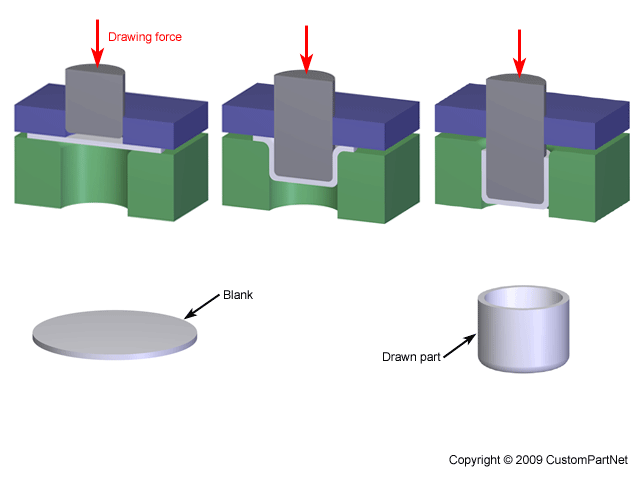

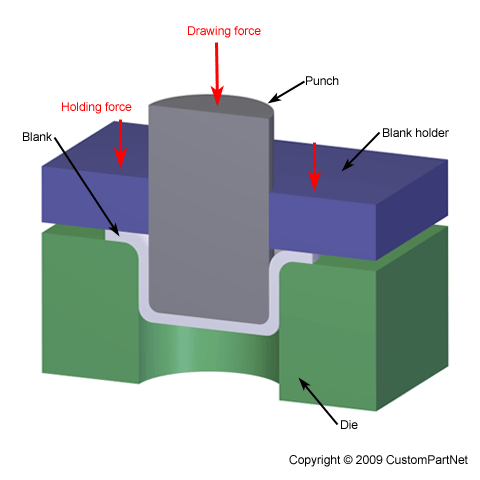

The punch is the desired shape of the base of the part once drawn.

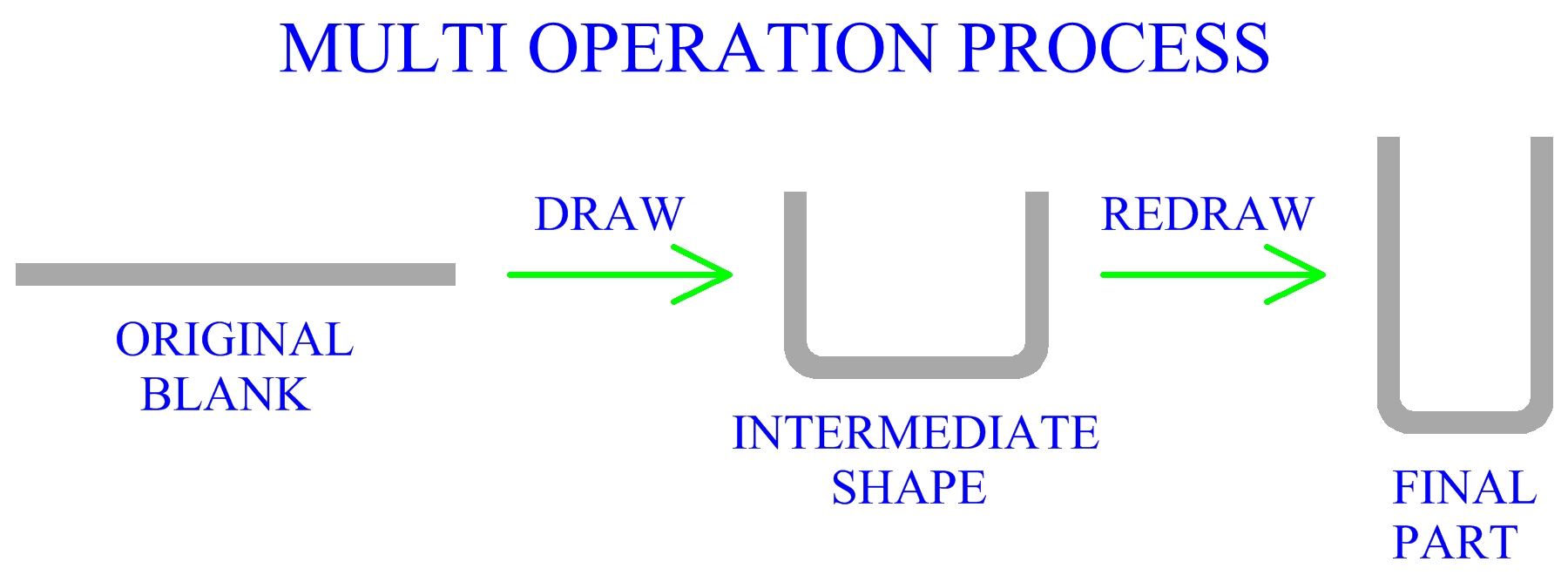

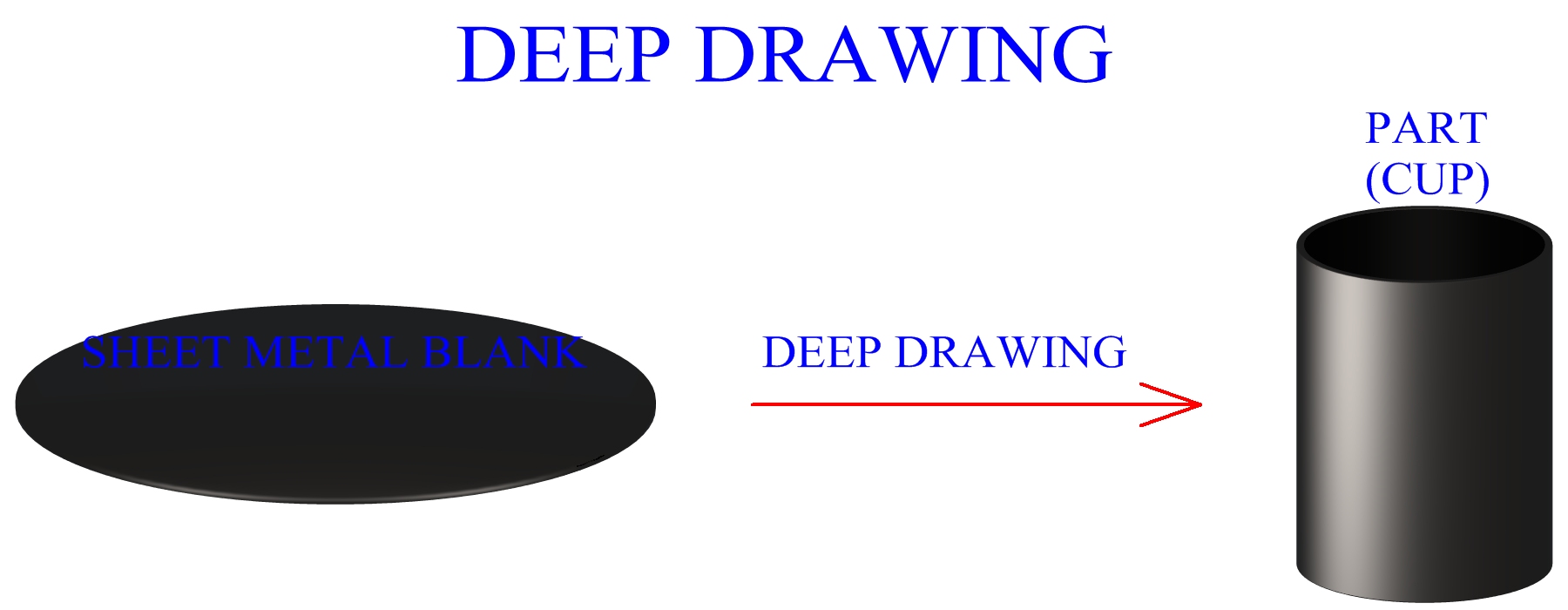

. Sheet metal is metal formed into thin flat pieces usually by an industrial process. Drawing is a metalworking process that uses tensile forces to stretch metal glass or plastic. Deep drawing is the metal forming process involving the redial drawing of a sheet blank to form a cylinder or dome-shaped component.

Sheet metal drawing is a metal forming operation in which the metal blank is stretched into a desired shape by the mechanical action of a punch. Sheet metal is one of the very convenient ways that is used in metal. Sheet Metal Drawing Operations - It is used to make cup-shaped box-shaped or other complex-curved and concave parts.

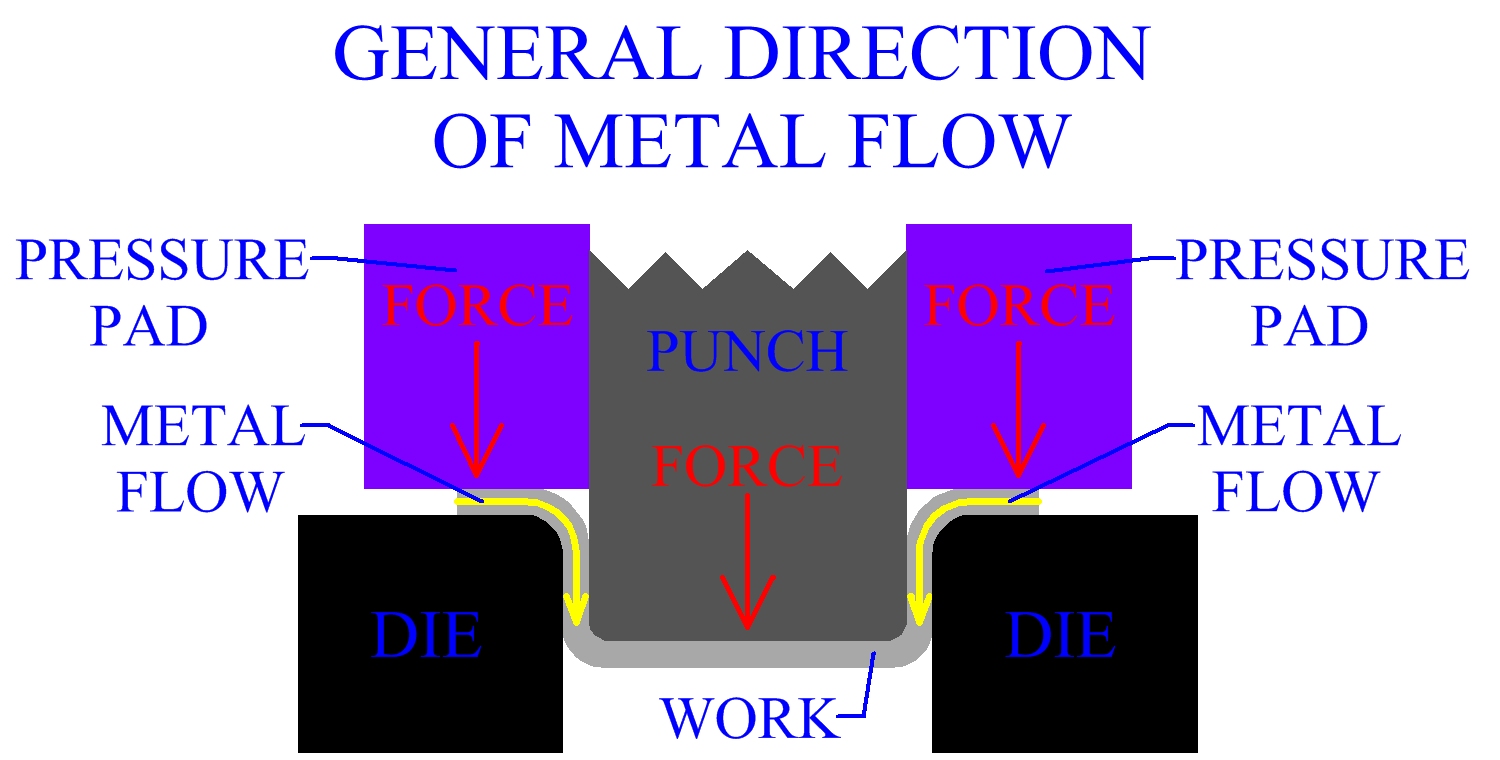

Usually a metal punch. Pressure pad is used to hold the base of the die while the punch forces the part to yield and bend over the edge of the. Drawing is accomplished by placing a piece of sheet.

What is Sheet Metal Forming ProcessIts 3 Types Explained 1 Bending Sheet metal bending is a metal forming process in which a force is applied to a sheet metal piece. Sheet Metal Operations - 1 MCQs are. Forming process are particular manufacturing process which make use of suitable stresses like compression tension shear or combined stresses which cause plastic.

Sheet metal is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of. - Figure 3-65 explains this process. Sheet Metal Operations - 1 questions and answers have been prepared according to the Mechanical Engineering exam syllabusThe Test.

School Atmiya Institute Of Technology. Shearing is basically a cutting operation. Hi FriendsIn this video you will learn Types of Drawing operations in sheet metal Common Defects in drawing operationRedrawingReverse redrawingDefects in.

Sheet metal drawing operation is used to make a wire. Drawing is a sheet-metal-forming operation used to make cup-shaped box-shaped or other complex-curved and concave parts by placing a piece of sheet metal over a. Bending operation that involves cantilever loading of the sheet metal.

Drawing is a sheet metalworking operation used to produce cup-shaped or box-shaped or other complex-curved an concave parts. You can use a shearing machine to cutshear a. Sheet metal drawing operation is used to make A wire B tube C cup shaped parts D.

The Last Guide to Sheet Metal Forming You Will Ever Need 1. The die cavity matches the punch and is a little wider to. Deep drawing of sheet metal is performed with a punch and die.

The punch pushes the. Drawing is a sheet-metal-forming operation used to make cup-shaped box-shaped or other complex-curved and concave parts by placing a piece of sheet metal over a die cavity.

Deep Drawing Operation In Sheet Metal Smlease Design

Sheet Metal Tools Cutting Marking Bending Tools

Pressing Deep Drawing Process Roy Mech

Deep Drawing An Overview Sciencedirect Topics

Sheet Metal Forming An Overview Sciencedirect Topics

Deep Drawing Process What Is It Formula Defects Calculation Applications Advantages With Pdf

What Is Deep Drawing Process Mech4study

Drawing Process An Overview Sciencedirect Topics

Deep Drawing Operation In Sheet Metal Smlease Design

Ironing Find Suppliers Processes Material